|

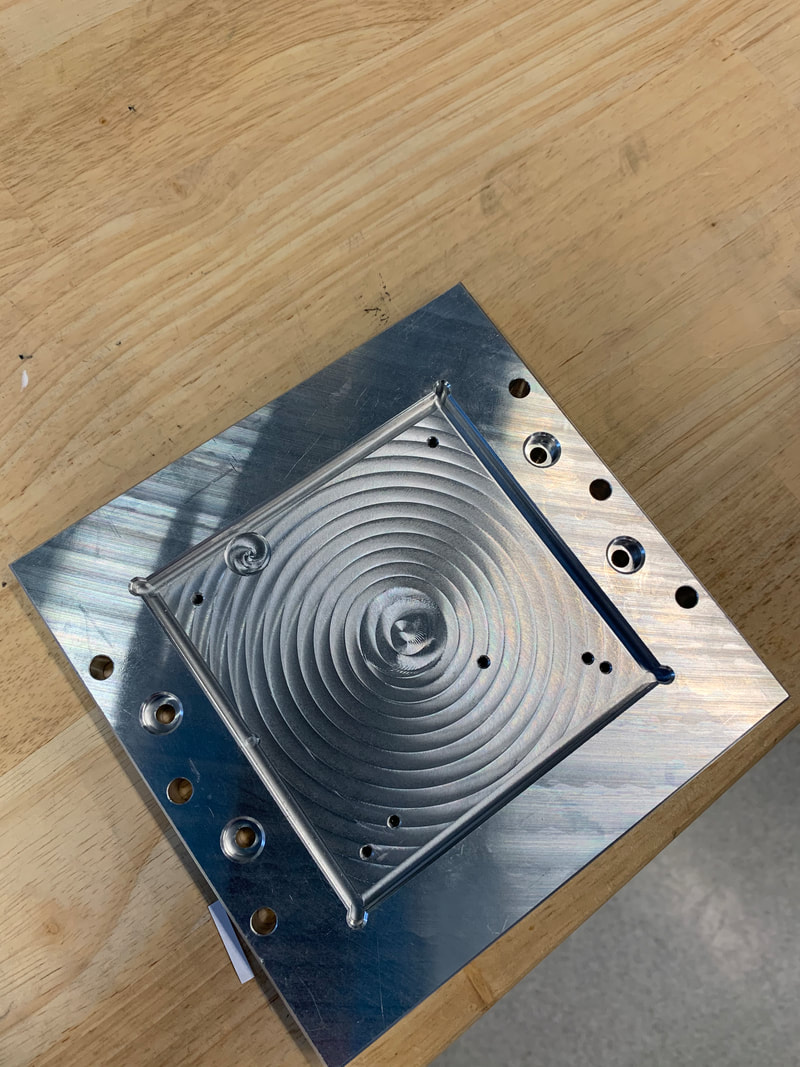

This weird fixture was designed to be used on the Carbide 3D and the Sherline CNC mini mill. Both tools are used to drill silicon wafers and microscope slides using tiny diamond coated drill bits. As this cutting process is abrasive and very heat sensitive, it must take place under coolant and lubrication to avoid frying the tiny coated drill bits. The edges of the recessed area as well as the corners are undercut to allow the slides and wafers to sit flush in the corners without worrying about the radius of the tool or the flute corner radius.

This was one of the first parts I machined on the Haas in the Microfluidics Lab, and let me say! Using a Renishaw touch probe to set tool height and part zero is one of the most magnificent things in the world, and cuts down on set up time by quite a bit! If I were to have to run this part again I could definitely cut down on cycle time by changing the order of some of the operations, and setting the stock high enough in the chuck that it is possible to chamfer the corner without a second set up. If you look closely at the left edge of the recessed area, you can also see a little bit of the lead in and lead out of the 1/8 inch undercutting end mill, and had I been a bit more confident in myself I would have set the tool to plunge or ramp for lead in and lead out along the undercut, but this 1/8 inch endmill was not center cutting, and this was my first time on this particular Haas.

0 Comments

|

Andrew FurstWelcome to my blog! This is a living breathing archive of what I wish to share about me personally with the world. Be prepared for weird music, and even weirder life updates. ArchivesCategories |

- Home

- About

-

Portfolio

- RPL Coaxial Swirl Injector

- Rhino Stent

- Microfluidics COC Research

- Research SLA 3D printer

- CMC Research - Daly Materials Lab

- 2022 Design Fair

- Random Lab Projects

- Mecanum Wheel

- Hack Pro

- Nat Car Adjustable Camera Mount

- Silicone 3D Printer

- Mini Mac (SFFPC)

- key cap

- HomeLab (Computing)

- Reverse Engineering LVTD's

- Home Lab (R&D)

- CV

- Contact

- Acclamations

RSS Feed

RSS Feed